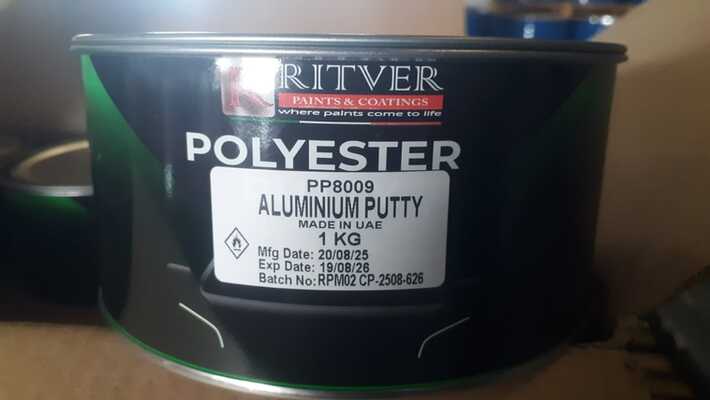

Ritver Polyester Aluminium putty is a two-part, aluminium-filled epoxy putty used for strong, non-rusting repairs on aluminium and other metal surfaces. When mixed, it cures into a hard, durable material that can be machined, drilled, or tapped using conventional metalworking tools. This makes it ideal for patching, rebuilding, and bonding metal parts in a variety of applications.

Common usesAutomotive repairs: Fill dents, fix cracks in engine blocks, or seal leaks in radiators and tanks. Some types are specifically designed for wheel repair....

Ritver Polyester Aluminium putty is a two-part, aluminium-filled epoxy putty used for strong, non-rusting repairs on aluminium and other metal surfaces. When mixed, it cures into a hard, durable material that can be machined, drilled, or tapped using conventional metalworking tools. This makes it ideal for patching, rebuilding, and bonding metal parts in a variety of applications.

Common usesAutomotive repairs: Fill dents, fix cracks in engine blocks, or seal leaks in radiators and tanks. Some types are specifically designed for wheel repair.Machinery and equipment: Mend aluminium castings, rebuild worn parts, or restore bearing housings. It is widely used in HVAC and industrial equipment maintenance.HVAC applications: Perform non-rusting repairs on aluminium machinery and equipment in heating, ventilation, and air conditioning systems.Marine repairs: Patch holes and seal leaks in boats and other aluminium watercraft.Prototypes and molding: Create lightweight prototypes, jigs, and fixtures for odd-shaped parts.General construction: Repair aluminium window frames, and bond aluminium or other metals to materials like wood, glass, masonry, and concrete.

How to use aluminium epoxy puttyPrepare the surface: Clean the area to be repaired by removing all oils, grease, and dirt. Roughen the surface with grit blasting or coarse grinding to improve adhesion.Mix the putty: Cut or add the required amount of hardener to the resin, following the manufacturer's instructions for the correct ratio. Knead or mix the two components thoroughly with a putty knife until a uniform, streak-free color is achieved.Apply the putty: Firmly press the mixed material into the prepared surface, ensuring it fills all cracks, voids, and holes. For large gaps, fiberglass or other material can be used as a bridge before applying the putty.Allow it to cure: Let the putty harden completely. The cure time varies by brand and temperature but can take several hours. Applying heat can accelerate the curing process.Finish the repair: Once fully cured, the repaired area can be machined, drilled, sanded, and painted to match the surrounding material.

Read More